- 0800 755 5269

- info@pat4less.co.uk

Services

Home

Tool Testing

Tools are the lifeblood of any trade site, and when they stop, the work stops.

From drills and grinders to extension reels and site lights, every tool is a link in the chain that keeps a project moving forward. A single unsafe or unreliable tool can cause delays, put workers at risk, and undermine confidence in the job. Tool testing is the safeguard that ensures the chain never breaks unexpectedly.

Trusted Documentation

Certificates accepted by insurers and regulators.

Low Price Guarantee

Transparent pricing with repairs included where possible.

Qualified Experts

All testing carried out by trained, accredited professionals.

Workforce Safety

Systematic testing reduces the risk of electrical shocks, burns, or failures, protecting the people who rely on tools every day.

Compliance

Detailed records and certificates show regulators, clients, and insurers that your equipment meets required safety standards.

Keep Working

By repairing minor faults on site and preventing failures, we keep your equipment available and your projects on schedule.

Unlike office appliances, tools live hard lives. They’re dragged across concrete floors, dropped from scaffolds, exposed to dust and moisture, and subjected to constant vibration. Even the best-made kit develops faults under that strain. A cable may look fine externally but be frayed internally; a plug may heat up under load; an insulation barrier may weaken gradually. Without systematic testing, these faults remain invisible until they trigger a failure — or worse, an accident. Tool testing is about getting ahead of those failures by finding the problems before they cause harm.

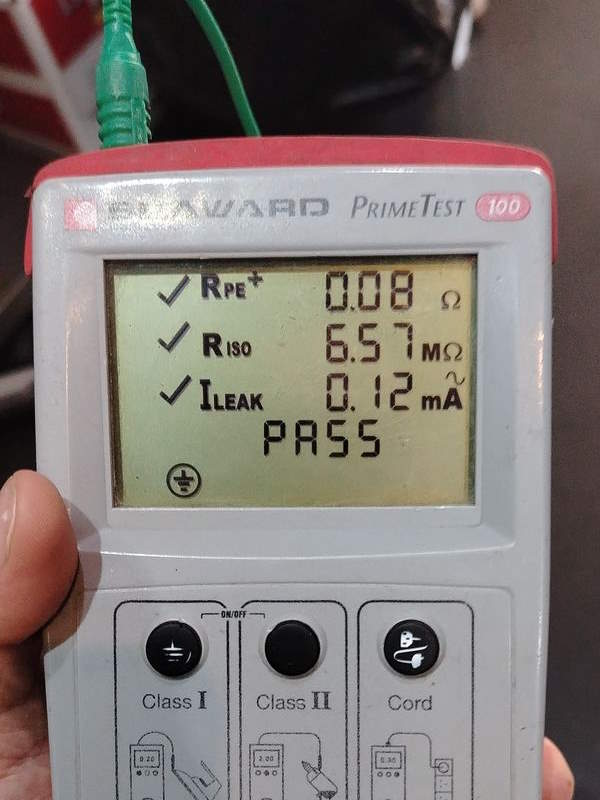

Our approach to tool testing is thorough and practical. Every tool undergoes both visual inspection and electrical testing tailored to heavy-duty use. We check 110V and 240V equipment with continuity tests, insulation resistance checks, polarity verification, and operational function tests. Where minor defects are identified — such as a cracked plug or a blown fuse — our engineers repair them on site whenever possible. That means the tool goes back into safe service immediately, rather than being pulled from circulation for days. This approach maximises uptime without compromising safety or standards.

Tool testing is not just compliance theatre; it is an operational necessity. Every failed tool in the middle of a job represents lost hours, extra cost, and sometimes contract penalties. Worse still, a serious fault can put workers at risk of injury, invite regulatory scrutiny, and damage a company’s reputation.

By embedding regular tool testing into your workflow, you extend the working life of your equipment, demonstrate a culture of responsibility, and avoid the spiralling costs that come from downtime or accidents. In short, it is both good safety and good business.

HAVE ANY QUESTIONS?

Get In Touch

Services

Your Electrical Safety Partner

P

A

T

4

L

E

S

S